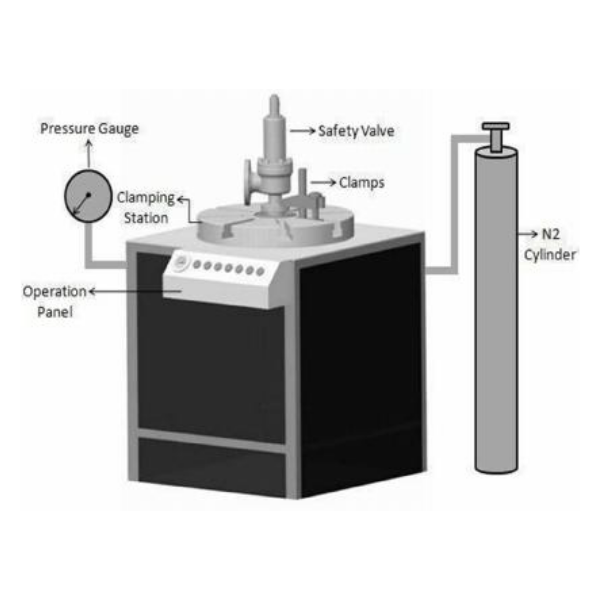

NAG-SV50

- Safety Valve Test Bench is a very easy, safe,

accurate and maintenance free operating work

shop test unit for Testing & Calibration of

pressure/safety relief valve (spring operated) in

the range of 0.5’’ to 8’’ (DN – 15 to 200 mm)

according to the common international test

standards. - Safety Valve Test Bench is designed to provide

the operator with a maximum of easiness to

calibrate the valves accurately.

- As standard manufacture, the four way manual sliding clamps allow an appreciable gain of time but, on option, pneumatic or hydraulic Machined body/nozzle casting can be fitted on bench.

- Unique – 4 claw clamping system, specially designed for quickly clamping all common types and sizes of safety valve up to 8’’. The specific configuration of the piping, fitting, and control ensure an

strong and dynamic lift reaction and accurate test result, high quality, stainless steel gauges

measure and display in pressure in kg/cm2 (g).

| Clamping Type | Manual – 4 Jaw System |

| Max. Valve Test Pressure | 230 bar |

| Tests Fluid Media | AIR/N2 |

| No .of Clamp Jaws | 4 Jaw System |

| Jaw Movement | 5”/SIDE |

| Sealing system | Face Sealing |

| Clamping Style | Flange to Test port mtg plate |

| Reference Standard | API 527 |

| Electric Supply for test Bench | Not required |

| Test Fluid Media | Nitrogen Gas |

| Valve end Flange Dimensions | As per ASME B 16.5 |

| Type of Valves | Pressure Safety Valves |

| Type of tests | Pop test, Leak test, Back Pressure test, Hydro test, Test medium as Water or air |

| Valve Clamp Table – Manual | 4 Jaw Zinc Plated, Manual Tightening with High Tensile Nut – Bolt System – Structural Frame with a T- Slot plate for manual Movement of Jaw and Support |

| Testing With Nitrogen (Direct from Bottle) | Pressure Regulator and Gauge will be provided on panel |

| Instrument Control Panel | Consists Nitrogen Regulator + Gauges, stainless Steel, precision regulated Needle Valve, Arrangement for mounting Test gauges, Arrangement for manual controlled valves/regulators for set pressure/leak tightness |

| Standard Test Gauges | Test Gauges : ±0.5% FSD, 160 mm Dial / GF / Bottom Connection/Bar -Range in Bar (0 – 10, 0 – 28, 0 – 60, 0 – 100, 0 – 160, 0 – 260 – S S PLATED) |

| Adaptor Plate with mounting Adaptors for NPT -Male Threaded type Inlet end connection Valves | Size : 1/2″, 3/4″, 1″, 1½” (M S PLATED) |

| Adaptor Plate with mounting Adaptors for NPT-Female Threaded type Inlet end connection Valves | Size : 1/2″, 3/4″, 1″, 11/2″, 2″-(M S PLATED) |

| Outer flanges suitable for | DN 15 /DN 20/DN 25/DN40/DN 50/DN 80/DN 100/DN 150/DN 200- (C – Clamp for Outer Clamp fixing with valve flange- M S PLATED) |

Tests that can be done

- Pop Test

- Leak Test

- Back Pressure Test

- Hydro test

- Test medium as Water or air/N2

Valve Sizes that can be tested

- Screwed connection: ½’’, ¾ ‘’, 1’’, 1½”

- Flange connection ½‘’ to 8’’

Valves Test Table & Control Panel

- Steel Construction, Valve mounting plate machined with eight/four equi-spaced grooves for easy movement of the clamping device. The control panel is located in the front of the table .A pressure gauge is fitted on the control panel to control the air supply.

Accessory Kits

- Screwed adaptor of size ½”, ¾”, 1”, 1½” Male type

- O-ring gasket sets

- Pressure gauge – 6 Nos. with Traceable Certificate

- Plates for Back Pressure Test

- Leak Test Device

- Spanners for adjusting sliding clamps

Optional

- Safety Valve Analyzer – Software

Downloads

Click here to download our product catalog