Calibration laboratories specialize in using quantification first devices to progressively change the precision of particular types of gauging and processing. Calibration aims to reduce measurement errors by verifying that test equipment is consistent. Calibration is the process of quantifying and controlling mistakes or possible errors in measuring operations to a safe level.

Increasing productivity using calibration management software

Adjusting the calibration transfer rate on how many properties can one employee calibrate each day is one of practically every laboratory’s performance indicators. The more assets that are properly calibrated during the workday, the more work a calibration lab can handle without hiring more people. You can see a significant boost in calibration throughput–up to 200 percent–by automating your calibration laboratory with calibration management software.

Improve Productivity with a Computer and Cal Lab Automation Software

Automation can boost a cal lab’s productivity by up to 200 percent. The systems calibration laboratories used to keep production working in the past were challenging to handle and time-consuming. For instance, a card on a whiteboard may be used to describe what stage of the process an asset is in, as well as who in the team is working on it. While it seemed like the simplest procedure at the time, there are numerous possibilities for this procedure to go wrong. Incorporating calibration management software to automate the system will help eliminate errors, speed up teamwork, save installation time, and involve minimal training to keep the workflow running well.

Calibration errors should be avoided

By incorporating calibration management software into your workflow, you can automate many processes and reduce errors. The metrology software may store calibration standards, ensuring that all technicians work with the same numbers and standards. Calibration automation software will trace where a device is in the calibration process at all times, both inside and outside of your lab. This includes knowing when a unit has shipped and where it is located in the lab. The program can guarantee that everyone in the lab, including your consumers, is aware of what has been completed and is being calibrated.

Using mobile calibration asset management software like MET/TEAM® Test Equipment Asset Management Software to minimize the number of manual touchpoints during the calibration. This helps eliminate numerous errors, resulting in less time spent double-checking or rebuilding assets which have already been finished.

Several calibrations are performed at the same time

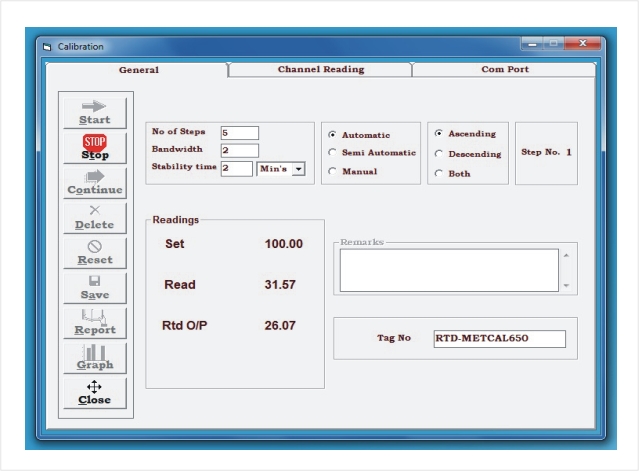

A technician can operate on multiple units simultaneously using automated software. Automated calibration software, such as MET/CAL Calibration Management Software, will get the proper figures for you depending on the asset, making it easier to get a unit functioning through the required stages and allowing a technician to calibrate many assets at once.

Setup time for mobile calibration is reduced

It can take a long time to set up assets, such as obtaining the proper information in your database or understanding the previous calibration data for a certain asset. All of this data can be saved in calibration management software, which can assist in speeding up the process. Rather than having to seek down each item, everything is kept in one place where technicians can go to find it.

Calibration training has never been easier

A Mobile Calibration Software suite may accelerate the calibration process by providing all of the information needed to get a procedure started. MET/SUPPORT with the help of Cubyt, a subsidiary of Gold, houses verified methods for large numbers of assets. These processes have previously been approved by metrologists or metrology technicians, so you can be confident that you’re working with accurate data.

Your lab won’t have to rely on an in-house metrologist to build each calibration procedure, which might be a constraint in a larger lab. MET/SUPPORT can assist you in supplementing the knowledge you already have so you can move quickly and decisively through the workflow.

How to get started

It can be difficult to set up calibration automation software, but here is where Calibration can support you. We work with you to build up and implement MET/CAL with both installation and training. We also help customers set up the system they require. If you have an expert assisting you every step along the way, the procedure will become a lot easier.

After this software is installed and operational, your calibration laboratory can start to experience gains in productivity while reducing stress on your staff and boosting throughput and productivity.

Benefits you enjoy in the long run

Productivity Improvements

- Calibration time is shorter by 30 percent or more.

- Rapidly calibrating new equipment

- Cut down on turnaround time.

- Enhanced flexibility for all disciplines as a result of increased laboratory capacity

- Instructions for calibration are incorporated.

- Wizards help you grow faster by allowing you to connect to nearly any instrument.

Quality Improvements

- Meets or exceeds all applicable quality standards

- A controlled and secure system is provided.

- Revisions to datasheets are managed by this program.

- Consistently fill up data sheets

- Transcription errors should be reduced or eliminated.

- Pass/Fail status is determined automatically.

- All calibration data is safely stored online.

- Provides a library of standard specifications.

- Consists of a standard SI Unit converter.