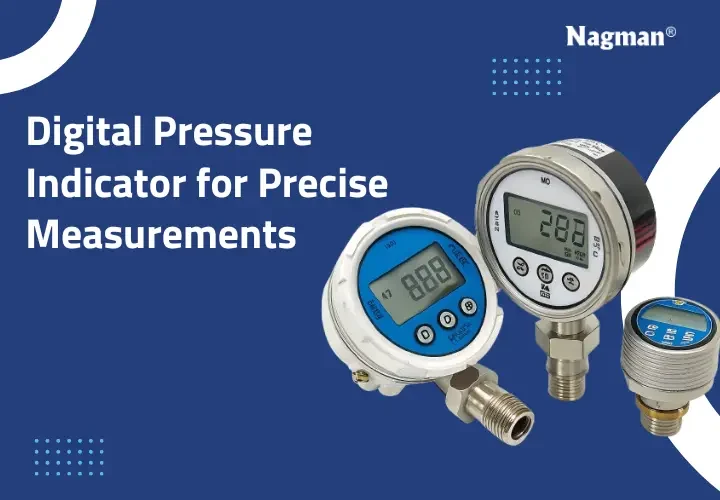

What Is a Digital Pressure Indicator?

A digital pressure indicator is an electronic device used to measure and display pressure with high accuracy in industrial and laboratory applications. It uses advanced electronic sensors to convert pressure into digital readings, ensuring precise and repeatable results. Unlike analogue gauges, it eliminates needle-reading errors and provides clear numerical values. Digital pressure indicators are widely used in manufacturing, energy, aerospace, and calibration environments where reliable pressure monitoring is essential.

Why Accurate Pressure Measurement Matters

Pressure plays a critical role in many industrial processes. In hydraulic systems, pneumatic operations, gas pipelines, medical devices, and testing laboratories, maintaining correct pressure levels ensures safety and operational stability.

Inaccurate pressure readings can lead to:

Equipment malfunction

Production inconsistencies

Safety hazards

Increased maintenance costs

Regulatory non-compliance

A digital pressure indicator reduces these risks by providing precise and stable readings, allowing engineers and technicians to monitor systems confidently.

How a Digital Pressure Indicator Works

A digital pressure indicator operates using electronic pressure sensors that convert physical pressure into electrical signals. These signals are processed internally and displayed as numerical values on a digital screen.

This method offers several advantages over analogue systems:

Eliminates parallax reading errors

Provides higher resolution

Enables quick interpretation

Ensures consistent measurement accuracy

Because readings are displayed clearly in numeric format, users can avoid misinterpretation that may occur with needle-based gauges.

Key Features of Digital Pressure Indicators

Modern digital pressure indicators are equipped with features that enhance performance and usability.

Accuracy and resolution:Designed to deliver precise measurements suitable for calibration and critical monitoring tasks.

Clear Digital display:Backlit screens allow easy reading even in low-light industrial environments.

Multiple Measurement Units:Users can switch between bar, psi, kPa, MPa, and other units depending on application requirements.

Data logging: Several models can store the readings to be referenced and analysed later.

Compact and portable design: Lightweight and convenient to use in the field or laboratory.

Connectivity options:Advanced indicators offer USB, RS232, or wireless connectivity for transferring data to external systems.

These features make digital pressure indicators versatile tools across multiple industries.

Applications of Digital Pressure Indicators

Digital pressure indicators are versatile and thus used for multiple applications:

Aerospace and defence: Making sure that measurements are accurate in critical test environments.

Healthcare: Designed for use in medical equipment and laboratory devices to ensure high levels of safety.

Energy sector: In pressure measurement of pipelines, gas plants, and refineries.

Research and development: Used to give precise readings of experiments which require accuracy.

Role in Pressure Gauge Calibration

Calibration is essential to maintain measurement reliability. In pressure gauge calibration procedures, high-accuracy electronic indicators are often used as reference standards.

By comparing readings from mechanical gauges against a certified reference device, technicians can identify deviations and adjust instruments accordingly. Routine instrument calibration ensures compliance with quality standards and prevents costly operational errors.

Accurate calibration improves equipment lifespan, reduces unexpected failures, and enhances workplace safety.

Advantages Over Conventional Gauges

Electronic pressure measurement instruments provide several advantages:

Improved precision

Reduced human error

Faster readings

Better data recording

Enhanced process control

These benefits make them ideal for industries that demand consistent and traceable measurement result.

How to Choose the Right Digital Pressure Indicator

Key considerations include:

Precision needs: Choose a tool that meets the accuracy requirements of your work.

Measurement range: Ensure that the indicator is compatible with the pressures encountered in your operations.

Portability: For on-site use, a lightweight, durable design should be the choice.

Data processing: If data processing is required, indicators with logging and connectivity capabilities are essential.

Budget and compliance: Strike a balance between cost and quality, ensuring the device functions within industry standards.

Future of Pressure Measurement Technology

The future of digital pressure indicators lies in smart integration and automation. With increasing adoption of Industry 4.0 technologies, pressure measurement devices are evolving to include:

Real-time monitoring

Cloud-based storage

Remote diagnostics

IoT integration

Predictive maintenance capabilities

These advancements allow industries to monitor systems continuously, detect issues early, and improve operational efficiency.

Conclusion

Accurate and reliable pressure measurement is essential for a wide range of applications. These instruments are widely used to improve pressure gauge calibration in high-precision industries. Thus, they help maintain uniformity and safety in daily operations.

With advancements in technology, their role is expected to grow further and set new standards in measurement accuracy.