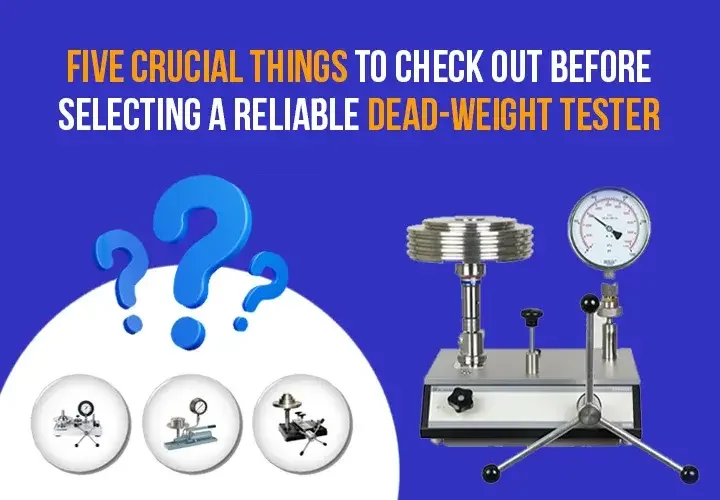

A dead weight tester is essential equipment for accurate pressure gauge calibration. These testers offer a reference pressure useful for precisely calibrating pressure gauges. Still, it might be challenging for everyone to select the best dead-weight tester due to the wide range of models available.

As a result, choosing the right dead weight tester to measure the accurate reading of pressure gauge calibration is crucial. You must identify the best option for your requirements and guarantee precise pressure readings. In this Nagman blog, we will do just that!

5 Important Factors to Note Down Before Choosing the Right Dead-Weight Tester

When picking the right tester for pressure calibration, these five important factors will help you make a good choice.

Precision and Accuracy

The main function of a deadweight tester is to deliver accurate pressure readings. The accuracy criteria of a deadweight calibrator should be considered carefully before choosing one.

Look for testers with excellent repeatability and accuracy to provide consistent calibration outcomes. Consider the tester’s resolution as instruments with greater resolutions may produce more accurate results.

Pressure Range

Selection of a deadweight tester that meets your calibration requirements is vital because they are available in various pressure capabilities. Consider the pressure gauge calibration that you’ll calibrate and select a deadweight tester to produce pressure within that range.

Choosing a tester with a large range of pressure gives you various choices to calibrate more types of gauges.

Portability and User-Friendly

Choosing a portable and user-friendly dead weight gauge tester is necessary depending on your requirement. When you often calibrate pressure gauges at several places, a lightweight/ portable tester will be more practical.

Look for testers that carry handles for convenient transition and optimum comfort. Select a tester that is easy to use to reduce the time and effort required for calibration.

Stability and Durability

Stability is an essential factor while calibrating dead weight pressure gauges. Consistent pressure creation is ensured by a sturdy tester, which produces precise calibration findings.

Imagine the tester’s design and materials, choosing strong & long-lasting models that can resist frequent usage. Seek tests with precise-machined parts and solid platforms to reduce vibrations and guarantee dependable operation over time.

Pressure Generation

A deadweight tester can produce pressure. Ensure the pressure tester you select can produce pressure consistently and reliably over its designated range. To guarantee proper pressure generation, look for testers with accurate piston-cylinder assemblies and effective weight sets.

Don’t Forget Calibration Standards and Traceability

Hence, it’s vital to abide by calibration guidelines and guarantee traceability to local, state, and federal standards during your pressure gauge calibration.

Select deadweight tests that meet the requirements of applicable standards, such as ANSI/NCSL Z540-1 and ISO 17025. Choose testers from respectable manufacturers who can provide traceable calibration certifications & services.

This guarantees the correctness and dependability of your calibration procedure. Considering factors such as accuracy, pressure range, portability, stability, pressure generation capabilities, calibration standards, and manufacturer reputation will help you choose a reliable dead-weight pressure tester for your pressure calibration.

Conclusion

Selecting the appropriate deadweight tester is essential for precise pressure calibration. You may choose a tester that satisfies your unique needs by considering elements, like accuracy, pressure range, portability, stability, and calibration standards.

Purchasing a top-notch dead weight calibrator can guarantee accurate and dependable measurements every time, regardless of whether you’re calibrating pressure gauges in a field or laboratory setting.

Additionally, keeping up with technological developments in calibration might enable using new features and capabilities to improve your calibration procedures. Selecting the appropriate dead weight tester is a continuous process that serves as the basis for accurate pressure gauge calibration. Are you in need of a deadweight tester? Nagman can help.

Get the best version of pressure calibrators only in Nagman!