No industry can deny the importance of calibration in assuring precise and accurate results. Regular calibration guarantees that the instruments are within a specified accuracy range, yielding reliable and consistent measurements over time. Our RTD calibration and verification also help with quality control, reducing the risk of faulty production. Here are the various types of calibration followed at Nagman Instruments to ensure timely and accurate outcomes:

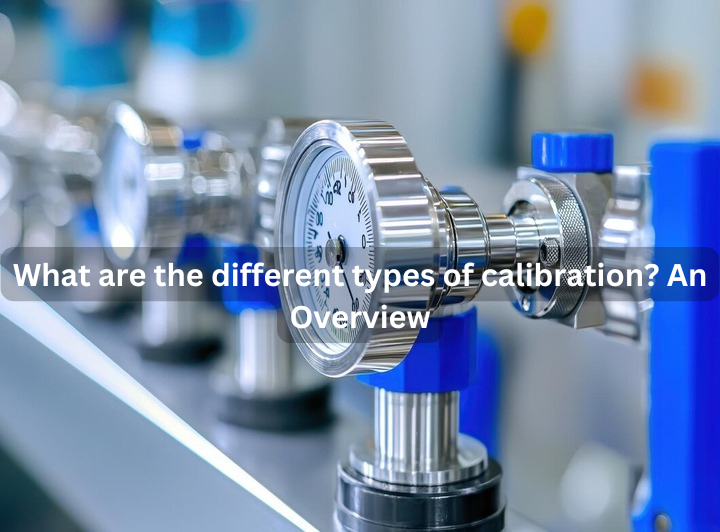

Pressure calibration

Pressure calibration plays a crucial role in maintaining quality assurance. Nagman pressure gauge calibrator, along with high-accuracy pressure sensors and pressure gauges are used to measure gas and hydraulic pressure to monitor performance and safety. We calibrate pressure instruments, including digital pressure gauges, digital indicators, transducers, transmitters, etc.

Temperature calibration

Nagman temperature calibrator aids in temperature calibration, which is crucial for industries working under controlled temperature environments. Temperature calibration is done by placing a thermometer in a stable reference environment and then comparing the reading to a reference thermometer. RTD calibration is necessary for instruments like thermometers, thermocouples, thermistors, freezers, furnaces, etc.

Pipette calibration

Pipette calibration is essential for laboratories to get precise experiment results. Vessels like single-channel, multi-channel manual pipettes and electronic pipettes need to follow various protocols in calibration to meet the desired experiment outcomes.

Electrical calibration

Electrical calibrations are done to measure electrical parameters like voltage, current, resistance, inductance, capacitance, time and frequency. Instruments like Multi-meters, oscilloscopes, frequency Counters, insulation Testers, and loop Testers need calibration for accurate results.

Mechanical calibration

Mechanical calibration involves calibrating factors like mass, force, dimension, angle, volume, flatness, torque and vibration in a temperature-controlled facility. Instruments frequently tested for mechanical calibration are Accelerometers, scales/Balances, load Cells & Force Gauges, micrometers, Verniers, Height Gauges, Torque Wrenches etc.

Flow calibration

Flow calibration measures the flow rate of liquid or gas in industries. This monitors the industrial flow processes in devices and determines the speed at which process fluid is moving through pipelines and vessels at a given condition. Thermal Mass Flowmeters, Laminar Flowmeters, Rotometers (Gas and Air) and Turbine Meters are some of the major flow instruments that need frequent calibration.

Apart from these, we also include some other calibration types, such as dynamic calibration, static calibration, field calibration, traceable calibration, master calibration, etc.

At Nagman Instruments, we ensure that industries and testing laboratories produce dependable readings and measurements. Our multifunction Process Calibrators measure the outputs and adjust them accordingly to industry standards. Gain confidence in your results with us! Contact us now.